Our Capabilities- CAMP

Mineral, metal, composite, and polymer: When it comes to characterizing your material, CAMP’s got you covered. Our capabilities include mechanical testing, hardness testing, metallography, failure surface analysis, corrosion analysis, elemental composition, and many other techniques. Browse the categories below to see our most common offerings.

If you don’t see what you need, contact us. We pride ourselves in method development and lab to bench scale research tailored to your needs. Our unique ability to partner with multiple departments across campus allows us to offer capabilities that may not be listed.

Analytical Lab Capabilities

Energy-dispersive X-ray Spectroscopy (EDS): Elemental analysis of bulk powders and solids by Energy-dispersive X-ray Spectroscopy (EDS) on the scanning electron microscope (SEM)

ICP-OES: Elemental analysis of aqueous solutions and digestates from solid materials by Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), based on the interaction of the material with a plasma. Available for more than 30 elements.

Arc Spark Optical Emission Spectroscopy (OES) Metal Analysis: Elemental analysis of iron, aluminum or titanium alloys. Wavelength range is 140-670 nm.

X-Ray Diffraction (XRD): Identification of mineral (crystalline) phases of bulk powders and solids at ambient and elevated temperatures (up to 1500 °C) in air, gas, or vacuum.

Automated Minerology: Automated mineralogical analysis of solids and bulk powders. Modal mineralogy, mineral liberation, mineral associations and grain size analysis are available.

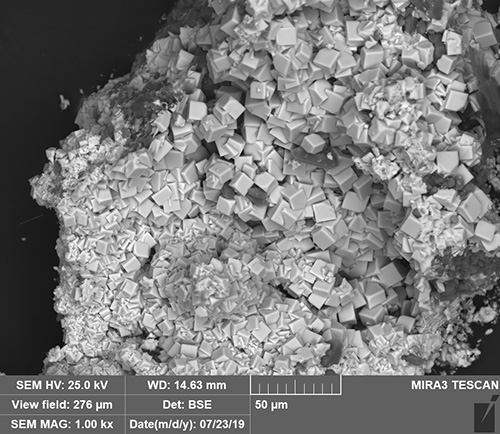

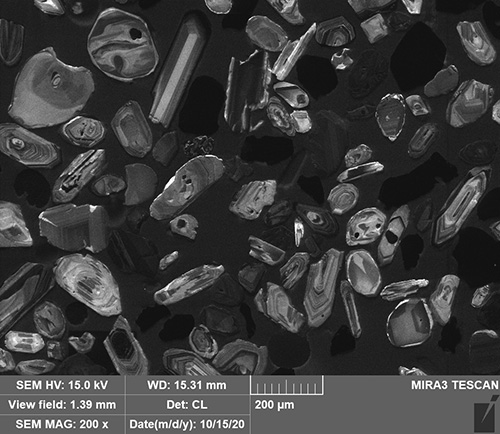

Scanning Electron Microscopy: Photographs of your material on the scanning electron microscope (SEM) using backscatter electron (BSE) imaging or cathodoluminescence (CL) imaging, up to 150,000X magnification.

CAMP SEM photograph of philsbornite, a rare arsenate mineral from the Centenario mine, Sierra Mojada mining district, Estado Coahuila, Mexico, collected by Stanley Korzeb. Permission to use courtesy of Montana Bureau of Mines & Geology.

CAMP CL photograph of detrital zircon from a Tertiary sandstone collected in southwest Montana by Jesse Mosolf. CL Imaging by Kristina Okonski. Permission to use courtesy of Montana Bureau of Mines & Geology.

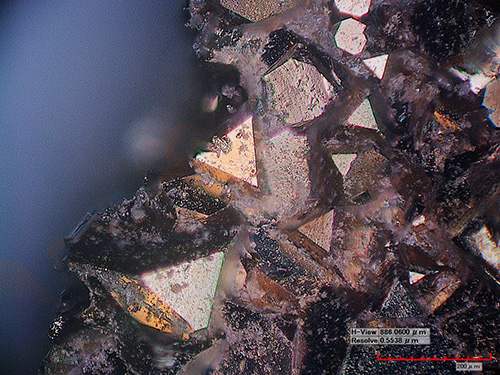

Hirox Digital Microscopy: Photographs of your material on the HiRox digital microscope, up to 3500X magnification, in color.

CAMP HiRox digital image of pyrite.

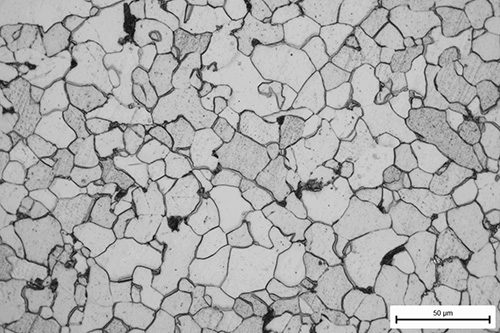

Reflected Light and Stereo Microscopy: Photomicrographs of your metal on a reflected light or stereo optical microscope, up to 100X magnification.

CAMP reflected light photomicrograph showing the grain structure of a steel pipe.

Contact us to inquire about our capabilities.

CAMP chemist Tina Stefanescu, conducting acid solubility testing of fracking sand (proppant) expressed as percent of undesirable (non-silica) contaminants.

Mineral separation of precious metals using the Mozley Laboratory “Super Panner” table, or heavy liquid separation (HLS). Data can be used for characterization of density, predicting the performance of ores in gravity circuits, or preconcentrating low grade, high density minerals. This technique is especially useful when studying gold-silver mineralogy.

Materials Lab Capabilities

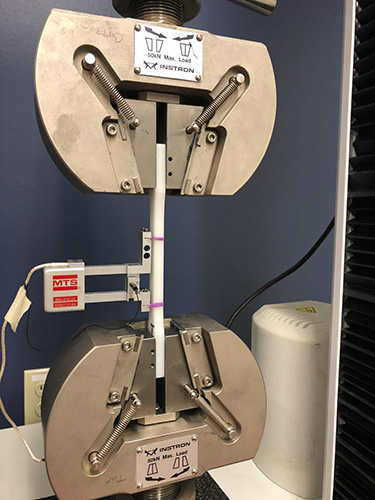

Our focus is materials characterization of composites, polymers, plastics, metals and wood, and our universal test frames are capable of testing loads up to 55,000 pounds. If you don’t see what you are looking for, contact us as we are available for method development and non-standard testing.

Quasistatic Testing

Tension Testing

Metals (ASTM E8)

Plastics (ASTM D638)

We also offer testing of composites (ASTM D3039) and speciality materials (please contact us). Modulus and Poisson's ratio also available.

Compression Testing

CAMP has capability for combined end-loading of composites (ASTM D6641). Modulus and Poisson's ratio also available.

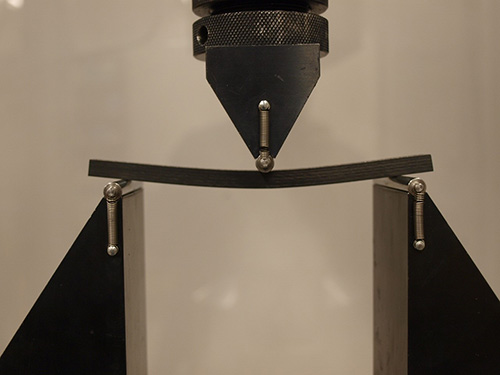

Flexure Testing

Plastics flexture (ASTM D790) and composites flexure (ASTM D7264/D7264M-21) are available.

Shear Testing

Short Beam Shear for composites (ASTM D2344) and V-Notch Shear for composites (ASTM D5379) are available.

Test Specimen Preparation

Our test specimen preparation capabilities include CNC machining of flat or round specimens, CNC machining of Charpy V-notch specimens, cutting and tabbing of composite specimens, and strain gauge application.

Dynamic Testing

Fracture and Fatigue Testing

Please contact us.

Impact Testing

Charpy Impact Resistacne

Maximum available energy 542 J (400 ft•lbf)

Split Hopkinson Pressure Bar

High strain rate compression of materials; heated chamber up to 500 °C; strain rates up to 104

Materials Characterization

Density / Specific Gravity

Density: Mass per unit volume; Specific Gravity: Ratio of density of a material to that of water at a specified temperature.

CAMP employees measuring the specific gravity of a wax fuel

Fiber and Resin Content, Fiber and Void Volume

Determination of the amount of fiber or non-matrix-material (fiber and filler) present in a composite, expressed as percent by weight or percent by volume. If no fillers exist, this is also called reinforcement content. Determination of resin content, or amount of matrix present specifically in a polymer matrix composite, expressed as percent by weight or percent by volume. For non-polymer matrix composites, this is called matrix content. With the addition of density data, volume percent of fiber, volume percent of resin, and void volume may also be calculated.

Fiber content testing by digestion

Fiber content testing by ignition

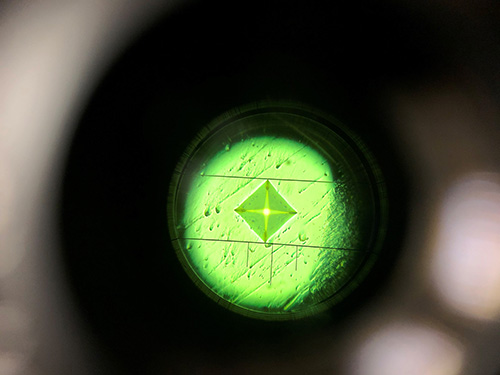

Hardness Testing

Vickers Microindentation

Microindentation testing is used to measure hardness of a material on a fine structural scale. ASTM E384-22 is followed for this test.

Shore D

Resistance of a material indentation, reported on the Shore D hardness scale, for composites, plastics, or rubber.

Rockwell Hardness

Rockwell hardness testing uses a diamon spherical or ball indenter to measure materials hardness; Rockwell A, B, and C available.

Contact us for your lab to bench scale needs if you don’t see what you are looking for.

Comminution

Reduction of ore particle size.

Gravity Separation

Separation and concentration of minerals based on their differences in specific gravity.

Magnetic and Electrostatic Separation

Separation and concentration of minerals based on their differences in magnetic strength using a magnetic belt or drum separator, or surface charge using an electrostatic separator.

Particle Size Analysis

Determination of the size and distribution of particles in a material, by sieving or microscopy.

Failure and Corrosion Analysis

When materials fail prematurely, the results can be catastrophic. We can conduct failure surface analysis by optical or scanning electron microscopy, and also have the capability to couple failure surface analysis with grain structure analysis, elemental analysis, EBSD, XRD, or mechanical testing to better understand the root cause of part or component failure.

Sample Preparation

Proper sample preparation assures that the inherent properties of your sample are being measured and limits debris, scratches or oxidation that can result in incorrect analysis. CAMP staff are well-versed in sample preparation requirements for metals, ceramics, geological materials, polymers, and everything in between, including sectioning, mounting, including hot mounting, grinding/polishing, and etching of metals.

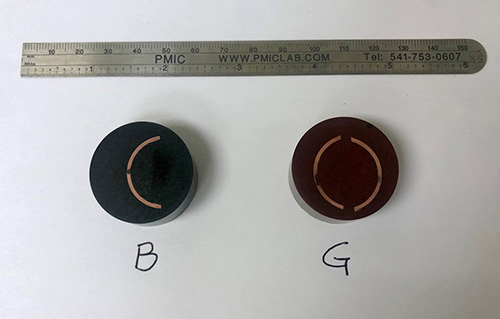

Mounted cross sections of a ¾” nominal copper pipe

Optical Microscope Imaging

CAMP offers imaging by reflected light or stero microscopy, up to 100X magnification, imaging by scanning electron microscope (secondary electron and backscatter electron) up to 250kX magnification, and HiRox digital imaging microscope, up to 3500X magnification in color.

Elemental Analysis

Arc/Spark optical emission metal analyzer is available for metals analysis. Scanning electron microscope energy dispersive spectroscopy (SEM-EDS) can be used for a wide range of materials.Electron Backscatter Diffraction (EBSD)

Electron backscatter diffraction, EBSD, is a powerful technique for investigation of grain structure and defects in crystalline mterials. Contact us to learn more about EBSD capabilities.

Thermal Gravimetric Analysis: Samples up to 1000 mg in inert or oxidizing atmosphere; ambient temperature up to 1000 °C (800 °C in oxidizing)

Simultaneous DSC/TGA: Samples up to 200 mg in inert or oxidizing atmosphere; ambient temperature up to 1500 °C

Thermal Treatments: Please contact us