Metallurgical/Mineral Processing Engineering, M.S.

Why Study Metallurgical/Mineral Processing Engineering at Montana Tech?

Montana Tech has awarded degrees in Metallurgical Engineering since 1922. Build upon our century of metallurgical and materials science expertise with a program that has a great track record of career opportunities and graduate placement.

Excellent Career Outcomes and Placement

Career opportunities and placement for graduate students in Metallurgical Engineering have been excellent. Companies who have hired our graduate students in recent years include Pegasus Gold; Kaiser Aluminum; Stillwater Mining Co.; Placer Dome U.S., Inc.; Newmont Gold Co.; American Barrick Resources Corp.; Santa Fe Pacific Gold Corp.; ASARCO, Inc.; Phelps Dodge Corp.; AMAX Gold, Inc.; Magma Metals Co., and the USBM.

Three options for individualized research

Graduate research may be pursued in any of three areas of concentration. Mineral Processing Engineering deals with the extraction, separation, and concentration of minerals from raw ores. Extractive Metallurgy focuses on refining processes, such as pyrometallurgy, hydrometallurgy, and electrometallurgy, through which concentrates are refined into a pure metal form. Materials Science emphasizes the study of physical and chemical properties associated with metals, ceramics, glasses, plastics, and slag.

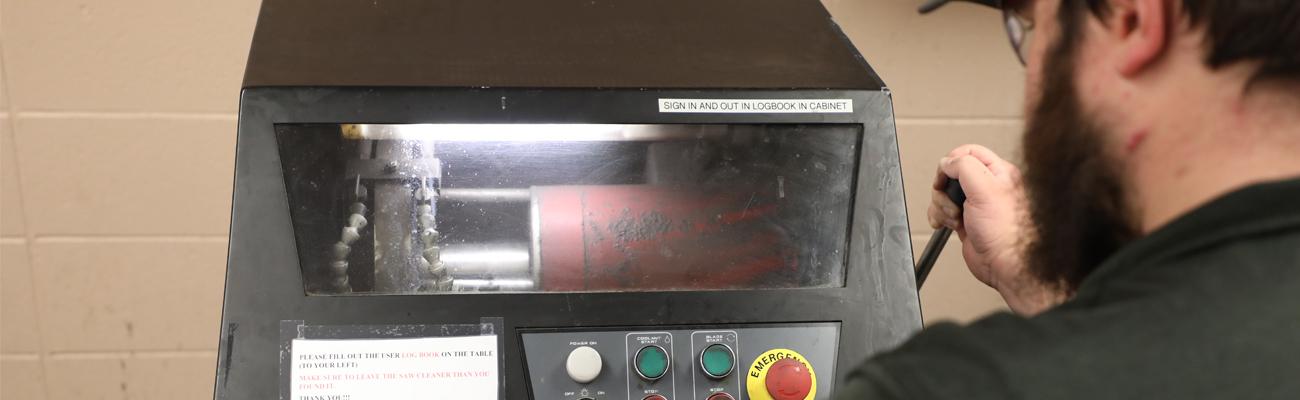

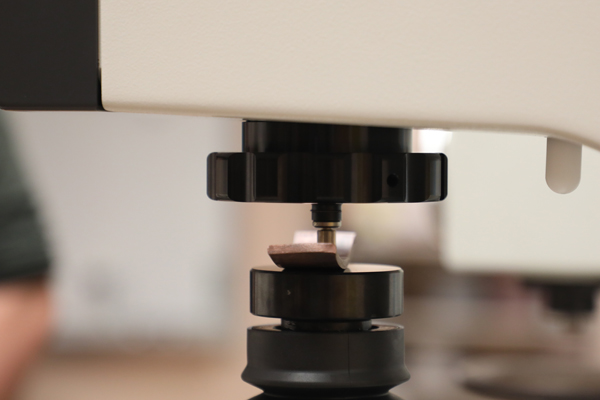

State-of-the-Art Labs and Equipment

Our labs help metallurgical engineering graduate students conduct research that makes an impact. Use state-of-the-art analytical, laboratory, and field equipment. You’ll have access to instruments in for your metallurgical engineering research and opportunities to work one-on-one with faculty.

Internships

Receive even more hands-on experience through a variety of metallurgical engineering internships in many employment areas, such as engineering consulting, biomaterials, or aerospace. As an in-demand metallurgical engineering student, you’ll have your pick of top internships in your area of interest.

Outstanding Location

While earning your graduate degree in materials science and engineering, you’ll also have countless opportunities to enjoy Montana’s great outdoors both in and around Butte as well as across the state. Butte boasts access to several ski hills, hot springs and a plethora of camping, hiking, road and biking locations.

5th Year Master’s

Qualified Montana Tech undergraduates have the opportunity to receive an accelerated MS degree by getting a jump start on required graduate coursework. Careful design to include qualifying graduate-level coursework into the undergraduate curriculum will lead to an accelerated MS degree.

What is Metallurgical and Materials Engineering?

Metallurgical and Materials Engineering is a diverse and interesting specialty that impacts nearly every facet of our economy. It applies chemistry, physics and math to recycling and treating wastes, separating minerals into concentrates, producing and purifying metals, manufacturing metals into products, creating materials, and joining materials together.

Metallurgical and Materials Engineering students learn the wonders of innovation and how materials can be manipulated to meet modern demand through a series of labs. As one of Montana Tech’s lab-based “heritage programs,” students reinforce theoretical concepts through “hands-on” experiential learning in laboratories that emphasize practical, industry-based exercises.

A Metallurgical and Materials Engineering degree leads to high-paying jobs in a broad spectrum of fields.

What Kinds of Jobs Do Metallurgical/ Mineral Processing Graduates Get?

Metallurgical/Mineral Processing graduates work with all aspects of metal and non-metal processing and manufacturing. Mineral processing engineers have the responsibility of accepting ore mined from the earth, comminuting the ore until liberation occurs, and then removing the valuable minerals in the form of concentrates. Extractive metallurgical engineers extract the valuable metals from the concentrates, remove impurities from the metals using aqueous or thermal chemistry, and then market the purified metal as a commodity. Physical metallurgical engineers accept various purified metals and alloy them to control a number of characteristics including strength and corrosion resistance. Materials engineers control the same characteristics but pertaining to plastics, composites, glasses, ceramics, etc.

Explore Classes in Metallurgical and Materials Processing

M.S. degrees in Metallurgical/Mineral Processing Engineering can be obtained by two options. Option A, the thesis option, requires 20 course credits, 8 thesis credits, and 3 seminar credits. Option B, the non-thesis option, requires 34 course credits and 3 seminar credits. Curricular programs will be established by the student and the graduate advisor in consultation with the graduate advisory committee. The student must demonstrate competence in both oral and written communication, advanced mathematics, and use of computers.

Off-campus research is encouraged. The degree requirements are the same as those described above for in-house research thesis projects. This allows students to pursue a thesis research project at their place of employment.

Meet faculty, explore our research expertise, etc.

Industry professionals guide our program.

Get semester-by-semester plans for graduation.

Become an expert in materials science by earning your Ph.D. Montana Technological University participates in the Materials Science Ph.D. program with Montana State University.

Earn your Ph.D. in Earth Science and Engineering and take advantage of Montana Tech’s and Montana Bureau of Mines and Geology’s distinctive strengths.

Prepares students for careers in materials-related fields including aerospace, biomaterials, chemicals, electronic materials, energy, and metals.

We can answer your questions and help you get started.

Professor and Department Head

jdowney@mtech.edu

406-496-4578