Popular display of glowing specimens back on display at The Mineral Museum thanks to help of Montana Tech Robotics Club

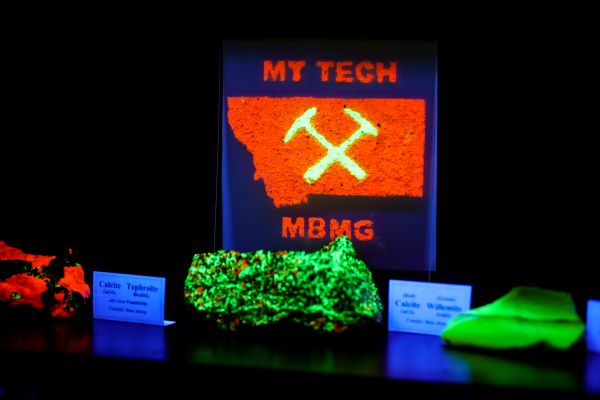

The most popular exhibit at The Mineral Museum at Montana Technological University, featuring fluorescent minerals that glow in the dark under UV light is back on display, thanks in part to the hard work of members of the Montana Tech Robotics Club.

The Mineral Museum re-opened in Spring 2024, after undergoing a remodel to remove asbestos-containing floors. The original maple hardwood floors underneath were refinished and now shine. Historic specimen cases were brought down from the museum’s upper level, and are being refit with aluminum case frames, improving lighting and security. Taller cases were moved to the periphery of the museum to improve overall sight lines.

The re-model also required relocation of the UV room, which exhibits dozens of specimens that are fluorescent under UV lights. Display cases were installed in what used to be the Earthquake Studies Office. A curtain was installed to make the space dark, and the Montana Tech Facilities team painted the walls and ceiling of the room black.

“It looked great, but now the question was ‘How do you get from white light to UV light, and have that on the timer, so that you don't have visitors, especially little kids, having to push the button all the time?’” Museum Director Steve Quane said. “I looked around and I found a vendor in Washington state. It was about $5,000 for a timer and I thought we could do better than that, this is an engineering school.”

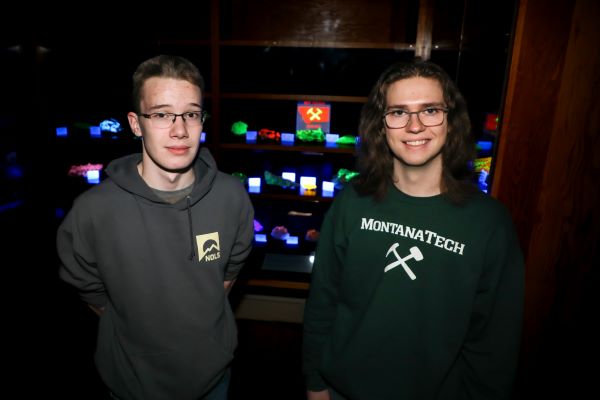

Senior electrical engineering student Dustin Marquardt, from Trout Creek, is president of the Montana Tech Robotics Club. He tackled the challenge along with club member Noah Barnhart, a freshman mechanical engineering student from Flagstaff, Arizona.

“The first step we took on the project was to evaluate what the Mineral Museum was hoping to accomplish with the new lighting setup, such as how many lights it would control, how users would operate the system, and if guests would be allowed to change the timer length,” Marquardt said. “With this information, we were able to determine what sort of off-the-shelf solutions were available, and what we would need if we wanted to develop our own device.”

The pair got to work developing a solution.

“We initially decided to develop our own outlet timer, as a custom device would be smaller and cheaper than suitable off-the-shelf solutions,” Marquardt said. “I designed an all-in-one printed circuit board (PCB) that contained the timer module and outlet control circuitry. I had previous experience with PCB design from several research projects and classes I completed with the Electrical Engineering department. These classes helped me understand what components were necessary for the project, and general design rules that shaped the final design of the timer.”

While Marquardt worked on the PCB, Barnhart started working on a separate element of the project.

"With Dustin working on the PCB design, that naturally left the questions of what the PCB was to be contained in,” Barnhart said. “Once he got the physical dimensions roughly defined, I went about making a 3D printed case for the timer circuit. It was relatively trivial to get a case designed in SolidWorks, a CAD program. After a couple of prototypes, the design worked well."

There were some challenges that arose on the project.

“We definitely ran into some issues along the way,” Marquardt said. “While the custom timer we developed was a compact solution, testing revealed some reliability issues, and that future maintenance could be difficult, as the Electrical Engineering department would have to assemble/repair any replacement PCBs. Ultimately, we decided on using off-the-shelf solutions to create a modular lighting timer, as it would benefit from using proven, professional designs. An added benefit was easier maintenance, as The Mineral Museum can order replacement parts from suppliers, and the modular design allows for replacing the timer or outlet control components separately.”

The changes also impacted Barnhart’s portion of the work.

"Because of the unfortunate reliability issues of the PCB, that meant the case was scrapped as well,” Barnhart said. “Once we decided on the off the shelf solution however, it did necessitate a small case to shield some of the components, which I was again able to provide with 3D printing and some light CAD design work."

Overall, Marquardt said he’s pleased with the outcome.

“While we didn’t use our custom design, the end product met the design requirements the Mineral Museum was looking for, and our club was able to make a contribution to one of its most popular exhibits,” he said.

The exhibit even includes a case where the public can bring their own samples, and stick them under the UV light to see if they glow. Not all rocks or minerals have the capability.

“It’s caused by certain impurities in the structure, but it doesn't mean any mineral with impurities will glow,” Quane said. “You have to have just the right combination.”

Approximately 5,000 visitors tour the Mineral Museum every year. Admission is free. The museum is open Monday through Friday from 9 a.m. to 4 p.m. during the school year. Check the museum website for summer hours.

For more information, click here. The Mineral Museum posts updates on upcoming events on the Montana Bureau of Mines and Geology’s social media pages. Follow them on Facebook here, Instagram here, and LinkedIn here.