Glass beadmaking, industrial tours, hands-on metal forging highlight weeklong summer camp

Thirty students from across Montana and the U.S. spent a week at Montana Technological University in late June at the Metallurgical and Materials Engineering Summer Program, hosted by the University’s Metallurgical and Materials Engineering Department.

This is the second year the camp was held, and it included new activities like trips to Montana Precision Products, Anaconda Foundry Fabrication Company, and glass beadmaking. Repeat activities from last year included casting medallions from aluminum, forging a steel knife with blacksmithing techniques, a trip to the World Museum of Mining and tours of industrial sites including the Continental Mine at Montana Resources.

“These camps are good for students to experience different fields, and get a test run for things they might want to go into,” Dr. Teagan Leitzke, one of the camp organizers said. “We give them a whirlwind tour of everything metallurgical and materials engineering, so they get a brief look into all the things that are out there, to show them all the things they can do, and different fields you can go into. If they are interested in engineering we want to show them all the things they can do in that field.”

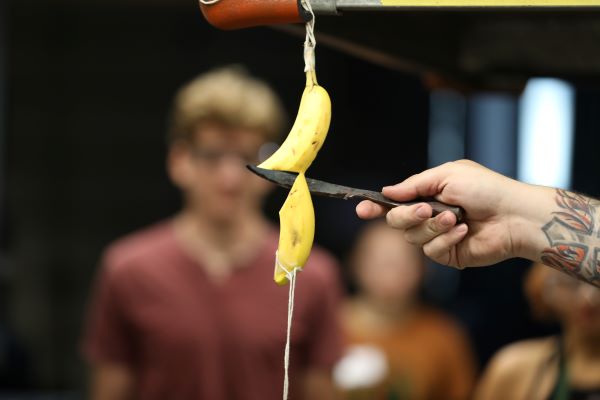

The grand finale of the camp included an event where groups put their knife blades to the test in an event called the Forge-a-Thon The blades were tested for hardness and ability to cut through watermelon and coconut. They also were expected to cut through a suspended banana. Camp organizers performed the cutting, and students were not allowed to take home their blades. The final 3-point bend test was performed to determine the maximum force each blade can withstand before failure.

“They really like the blacksmithing aspect, which is a returning favorite, but the newest highlight was our glass beadmaking,” said Dr. Grant Wallace, one of the camp organizers. “It was a pretty popular event this year. Our new Nucor professor Basak Anameric set up a station where they learned about glass properties, and got to do some artwork. It combined the engineering with the art, and they seemed to have a great time working with fire and hot glass.”

The beadmaking exercise highlights the diversity of materials the Metallurgical and Materials Engineering Department works with.

“It’s not just metals,” Wallace said. “We cover everything from ceramics to polymers, composite materials, mineral processing and extractive metallurgy. We are an all-encompassing department when it comes to materials. We’re not just metals. We do it all.”

Austin Beaver, of Sacramento, California, said he is now more interested in Montana Tech’s Metallurgical and Materials program after the camp. Beaver has been dead set on going into engineering for the past couple of years, but he is unsure if materials engineering will be his specialty.

“I was bored for the summer, and needed something to do, so I was looking online and found this camp,” Beaver said. “I enjoyed pretty much every day. My favorite part was the glass bead making because Bashak was overwhelming in her passion. I am more interested in the program and what she is involved in. It’s a free camp. There’s really no reason not to go. The instructors are overwhelming with passion here and it was nice to see how much effort they put in.”

Robert Spore also flew from Sacramento, California, and attended the camp for a second year, and said the forging event and the visit to the Continental Mine were his favorite parts of camp.

“I wanted to come back and do it again because I had a lot of fun last year,” Spore said. “After going to these camps and the football camp, I definitely think Montana Tech is on my college options list. After coming to these camps and learning more about materials engineering, I think that is something I would be interested in doing in the future and getting a degree in.”

Alex Jasperson of Missoula said camp was fun and that his favorite part was seeing people working in industrial settings.

“It gave me a good idea of careers I might want to do in the future,” Jasperson said. “It’s a great way to explore some new things. I had never been in an active mine before, so having the opportunity to see people at work was great. It was also a great way to learn about the history of Montana and Butte.”

In addition to learning about materials science and engineering, camp attendees also made lasting friendships through activities like making s’mores, eating pizza from Gallicano's and seeing a show at the historic Washoe Theatre in Anaconda, and more. Last year, Maddy Noland of White Sulphur Springs, and Anna Mwaniki, of Laurel, met at the camp. Despite the 118-mile distance between their hometowns, the pair stayed in touch and became friends. They both came back to camp this year.

“A huge part is that you get to make STEM friends,” Mwaniki said.

Wallace said five students from the first camp are enrolled for Fall 2024. Plans for the 2025 camp are underway. Donations fund the camp, with the majority coming from Day One sponsorship. To contribute, click here.