Montana Technological University students developing system to extract lithium from oil and gas wastewater

Montana Tech students are designing a system to separate lithium from wastewater produced by drilling petroleum and natural gas wells.

Lithium is a rare element critical to producing rechargeable batteries found in cars, phones, and the power grid. The element is so critical to power infrastructure in the U.S. that the Department of Defense has an official Lithium Battery Strategy to ensure affordable domestic supply chains of lithium.

The idea to extract lithium from oil and gas wastewater is one which several major energy producers have announced they are exploring in the past two years, and seniors in Dr. Robin Bullock and Dr. Rick LaDouceur’s senior design class decided to see if they could deliver a product to make this theoretical proposition a reality.

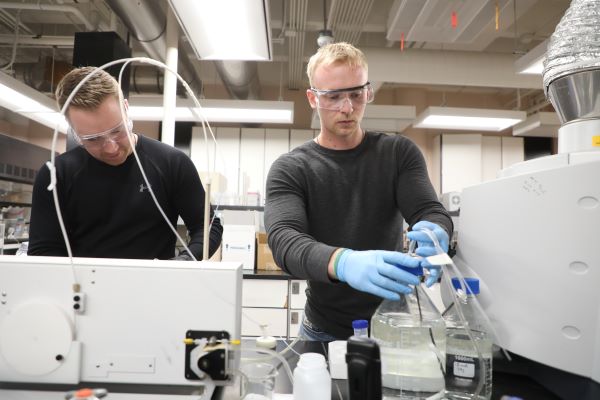

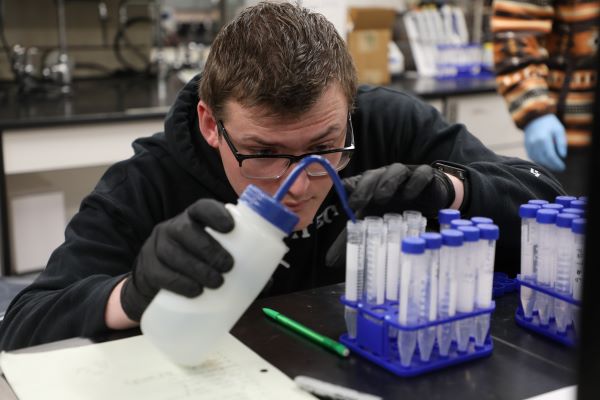

The team consists of environmental engineering majors Zayne Sanborn and Daniel Dobson and mechanical engineering majors Riley Boese, Zachary Boles, and Logan Marlow.

“We focused on the lithium adsorption column,” Boles said. “We hope to have a foundation for the future, so other students can work off our design and make it into a totally efficient and economically feasible large-scale operation that can be deployed at well sites around the world.”

The adsorption column consists of a tank and one filter. It utilizes iron phosphate, which is produced as a byproduct of operations at the Solvay USA chemical plant in Ramsay. Other critical pieces of the design include a clarifier and an elution tank.

The team’s prototype has shown promising results so far, though they want to continue working in the lab to make sure results are accurate and replicable with isotherm data.

“We were able to have a pretty decent recovery early on,” Sandborn said. “At about 10 minutes, we saw about 95% recovery of lithium from a standard lithium solution.”

Though the results are encouraging, the team acknowledges some potential roadblocks to recovering lithium from oil and gas wastewater. Economic factors could be a big one.

“The first concern is market volatility,” Boese said. “Fluctuations in the lithium market, as well as the oil and gas market can be unpredictable.”

While markets might be a wild card to the project’s potential profitability, the team believes there is both potential economic and environmental value to the design.

“As lithium becomes a more valuable resource due to energy transitions, the team believes that the continuation of the design can help to curb impacts that traditional methods, such as mining, have on the environment,” Sanborn said. “The system could also provide an additional cash flow to the facilities that operate it, further increasing the value of the system. It could be managed around the market for lithium as well by making the system an add-on module, allowing companies to operate when economically acceptable. There is always opportunity to continue and improve upon the design and achieve greater optimization to create a new way to produce lithium."

The team will present their research at the 13th Annual Techxpo Design Showcase on April 25, 2024 in the Montana Tech HPER.