Montana Tech graduate students take fifth place at SME conference with critical mineral extraction poster

Two Montana Technological University Materials Science Ph.D. students are working in Dr. Richard LaDouceur’s laboratory to find more sustainable and economical methods of obtaining samarium-cobalt through recycling. The current process of extracting critical minerals from ore is limited by high monetary and environmental costs.

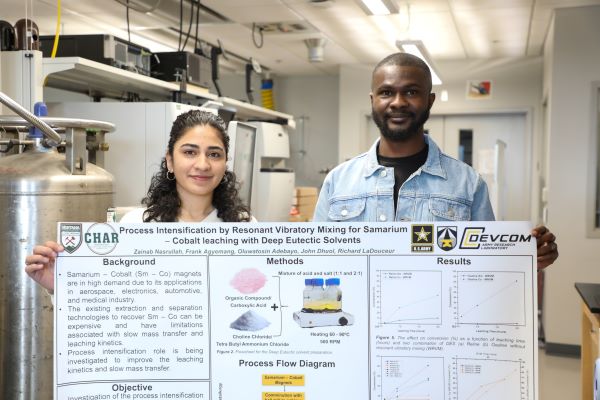

Frank Agyemang, from Kumasi, Ghana, and Zainab Nasrullah from Lahore, Pakistan, presented a research poster on their project, “Process intensification by resonant vibratory mixing for the recyclable Samarium - Cobalt leaching with deep eutectic solvents,” at the Society for Mining, Metallurgy & Exploration (SME) annual conference in Phoenix, Arizona. It took fifth place among 70 competitors from top universities.

“Zainab and Frank’s approach to the research has exceeded all my expectations,” said Assistant Professor LaDouceur. “Their work is already being recognized at the national level, and when you consider neither has even taken their qualifying examinations yet, it shows how well they will do in their doctoral work and whatever they decide to do after.”

It was the first time Nasrullah attended the SME conference, which attracts thousands of participants.

“The impact of the conference was that I learned more about what was happening in my field from others through the poster competition,” Nasrullah said. “There were competitors from Penn State, West Virginia, and other universities. When you learn more about what’s happening in your field, it helps you move forward in your research.”

The research project was funded through a Cooperative Agreement with the DEVCOM Army Research Laboratory that was made possible by the support of Senator Jon Tester. Agyemang and Nasrullah want to find ways to recycle samarium-cobalt from waste samarium-cobalt permanent magnets. The rare-earth material samarium is used to create strong permanent magnets together with cobalt for high-temperature applications such as the aerospace and automotive industries, but it is only found in trace amounts.

“Right now, extraction and separation of samarium from the primary source, like ore, is very difficult since rare earth elements are chemically stable together and occur in trace amounts,” Agyemang said. “You can’t just choose a cheap way to process it, hence there is a need for a secondary source, which is the recycling from the waste.”

The leaching process currently uses conventional reagents to extract the rare earth elements, which are expensive and toxic to the environment. The process itself can also involve slow leaching kinetics. China also holds a near monopoly on the processing of rare earth elements. If the researchers can find an economical and more environmentally friendly way to recycle samarium–cobalt, it could have impacts that reverberate through numerous industries.

“We hope to successfully develop technologies that can extract and separate rare earth elements in a manner that is both environmentally friendly and cost efficient,” Nasrullah said. “Once achieved, industries can leverage these advanced technologies for a wide range of applications involving rare earth elements.”

By August, the pair hopes to have good results to finalize the project, which has taken about half a year to complete. They’ll move on to other projects after that. Nasrullah is expected to graduate in 2026, and Agyemang will graduate in 2027.